Resources

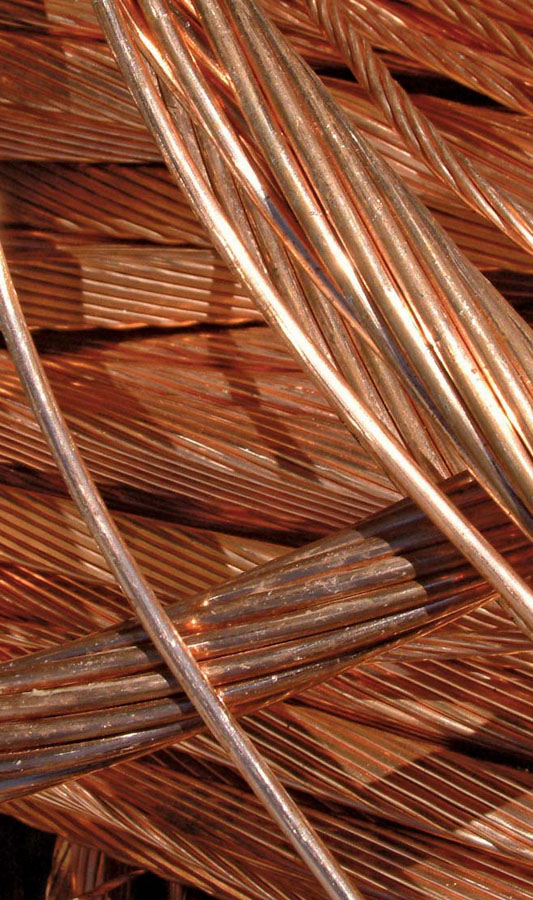

What is Copper?

Copper is a non-ferrous transition metal. Unlike brass and bronze, it is a pure, naturally occurring metal; therefore, it is found on the periodic table of elements. It is among the few metals found in nature that is directly suitable for processing. Although it is used on its own, it is also combined with other pure metals and alloys to form its own subset of alloys.

Key Properties of Copper Alloys: Copper is a tough, ductile and malleable material. These properties make copper extremely suitable for tube forming, wire drawing, spinning and deep drawing. The other key properties exhibited by copper and its alloys include:

Applications of Copper : Copper and copper alloy can be used in an extraordinary range of applications. Some of these applications include:

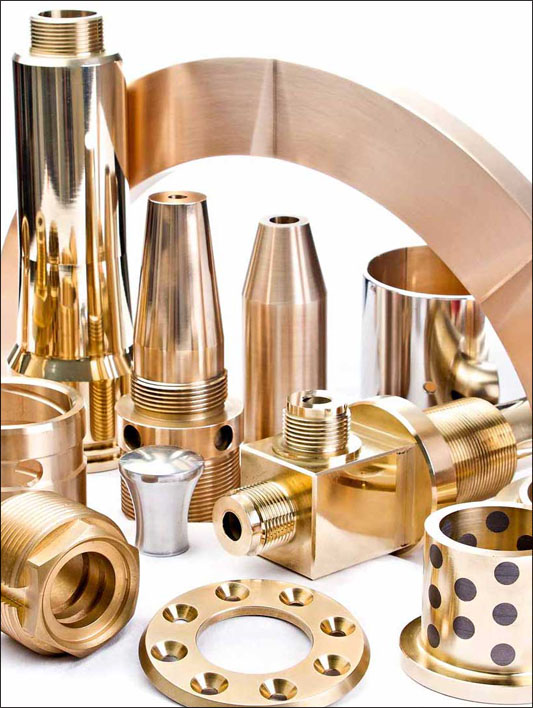

What is Brass?

Like copper, brass is a non-ferrous, red metal. Unlike the pure metal, however, it is a metal alloy that primarily consists of copper and zinc. Other metals—such as lead, tin, iron, aluminum, silicon, and manganese—are also added to produce more unique combinations of characteristics. The addition of zinc enhances the strength and ductility of the base copper material. The higher the concentration of zinc, the stronger and more pliable the alloy. High-strength brass contains ≥39% zinc.

Properties of Brass : As a copper-alloy, brass demonstrates many of the properties characteristic of copper. However, the alloy does exhibit a few distinct properties compared to pure copper and other copper alloys. For example:

Applications of Brass : Brass and brass alloy can be used in an extraordinary range of applications. Some of these applications include:

What is Bronze?

Bronze is a copper-based alloy that typically consists of approximately 88% copper and 12% tin. Trace amounts of other metals, such as aluminum, manganese, phosphorus, and silicon, may also be present in the alloy.

Properties of Bronze : Many of the properties of bronze overlap with those of copper and brass. For example:

Applications of Bronze : Bronze and bronze alloy can be used in an extraordinary range of applications. Some of these applications include: